Green hydrogen is key to the energy transition. While currently expensive, it could become cost-competitive within a decade with economies of scale, technological advancements, and policy support. India’s abundant renewable energy offers a significant advantage.

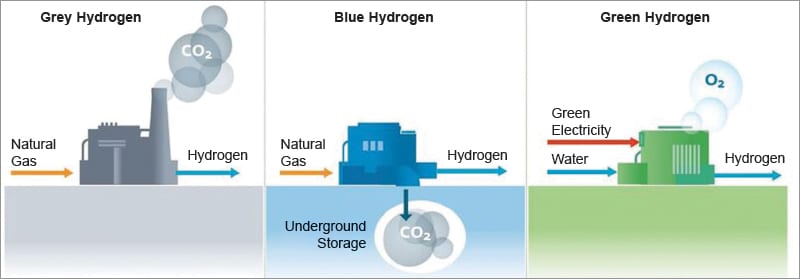

Green hydrogen (GH) is attracting worldwide attention and emerging as the most promising solution for a cleaner, greener, and sustainable future. Depending on the method used for the production, hydrogen is categorised into three types, grey, blue, and green—as shown in Fig. 1. Grey hydrogen is produced using fossil fuels such as natural gas or coal. The processes that are used, the steam methane reforming and the coal gasification, release a significant amount of carbon dioxide (CO2) into the atmosphere. Grey hydrogen is the cheapest and most used form and accounts for about 95% of the hydrogen produced in the world. Blue hydrogen is produced using the same methods as used for the grey hydrogen, except that most of the CO2 produced is sequestered (stored in the ground) using the carbon capture and storage (CCS) methodology. Capturing and storing the CO2 emissions, instead of releasing them into the atmosphere, makes the blue hydrogen a lower-carbon fuel as compared to the grey hydrogen.

Types of hydrogen fuel (Source: https://energyeducation.ca/encyclopedia)GH on the other hand is produced by the electrolysis of water using the clean renewable energy produced by sources such as wind and solar. The process emits only water vapour, leaving no residue in the air, which makes GH the cleanest energy source.

GH, presently, has a low share in the global energy market since it is very expensive to produce. Efforts are being made to reduce the costs. As per the estimate of International Renewable Energy Agency (IRENA), an 80% drop in cost is possible by the year 2030, provided the cost of electrolysers is reduced and the renewable energy cost dips below US$20/MWh.

Processes used to produce green hydrogen

Please register to view this article or log in below. Tip: Please subscribe to EFY Prime to read the Prime articles.